rockwell hardness tester machine|rockwell hardness testing machine diagram : company The ZwickRoell Indentec Rockwell hardness testers with dead weights and . Resultado da The AI deepfake feature on Deep-Nude.ai has made the process of creating faceswaps extremely simple for all users, without requiring extensive .

{plog:ftitle_list}

16 de mar. de 2017 · Universe sandbox 2 - faça o download em Português versão gratuito para celular ou tablet Android. Versão completa do arquivo apk. Sem registrar. Universe .

ZwickRoell offers various models of Rockwell hardness testers for metals, plastics, ceramics and carbon. Learn how a Rockwell hardness tester works, what test methods it uses and .Achieve reliable test results with the ZHR8150CLK hardness tester—for .

The ZwickRoell Indentec Rockwell hardness testers with dead weights and . RH2150 Series prioritizes flexibility, ergonomic testing, and swift data output. Get more done with the Wilson RH2150 Rockwell Hardness .

Buehler offers various models of Rockwell hardness testers for metallographic sample preparation, with different vertical capacities, scales, and features. Learn about the Rockwell 2000, Wilson 574, and RH2150 series and their .Achieve reliable test results with the ZHR8150CLK hardness tester—for more than 30 different depth-measurement applications, including Rockwell for metals and ball indentation hardness for plastics.Testing Machine. HR-530 series of hardness testers Rockwell testing of plastics testing. HR-530 (810-233-23A) Maximum specimen size: Height 250 mm, Depth 150 mm. Graphic display of .Learn all you need to know about Rockwell hardness testing – including test definitions, test calculations and insight into Rockwell hardness testing machines and HRC hardness testers – with knowledge and expertise from .

The ZwickRoell Indentec Rockwell hardness testers with dead weights and frictionless load application. Available in different configurations for both classic Rockwell and superficial Rockwell hardness testing.

The Tru-Blue II Rockwell Hardness Tester is built for durability, precision and ease of use, complete with a removable clamping device that secures your test, reducing operator influence.

This hardness testing machine is ideal for applications ranging from high volume to sampling, from production floor harsh environments to the lab and from testing awkward shaped parts to .Rockwell hardness testing machine has transformed how you assess material hardness, making it the go-to solution for professionals seeking unparalleled precision. From metals and alloys to plastics and ceramics, the Rockwell .A Rockwell hardness tester. The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the .Rockwell Hardness Testers – Bench Analog Models Analog Rockwell Hardness Tester Phase II - Model 900-331 Rockwell Superficial Hardness Tester Phase II - Model 900-345 Rockwell/Superficial Twin Hardness Tester .

The various hardness testers in the Rockwell product group perform classical Rockwell methods (load: 60 - 150 kg), superficial Rockwell methods (load: 15 - 45 kg) and combinations of Rockwell and superficial Rockwell methods .Series 810 - Rockwell Type Hardness Testing Machines. FEATURES. Multiple test force generation for Rockwell, Rockwell Superficial and Brinell hardness. Dolphin-nose indenter arm for easy reach of interior (min. ø40mm/ø22mm*) and exterior surfaces.Rockwell hardness test measures the permanent depth of indentation on the material by applying a fixed load using an indenter. The smaller the indentation value, the harder is the material. The Rockwell hardness test follows the principle of the differential-depth method. Here, the indenter makes a residual depth called the indent and it is .CRYSTA-Apex V Series CNC Coordinate Measuring Machines. Search for: Menu. Mitutoyo > Products and Solutions > Test Equipment. Test Equipment. . Rockwell Hardness Testers; Portable Hardness Testers; Micro Hardness Testers; Mitutoyo products are intended for industrial use only. They should be used strictly in accordance with the instructions .

The Rockwell Hardness Test also uses superficial scales. These use lower loads and shallower indentions and are useful when a sample may be too brittle or thin for a standard Rockwell hardness test. Superficial Rockwell hardness tester: 15N, 30N, 45N, 15T, 30T, 45T, 15W, 30W, 45W, 15X, 30X, 45X, 15Y, 30Y, 45Y Polymer/Plastic ScalesLike all ZwickRoell Rockwell hardness testers, these instruments support fast, accurate and efficient hardness testing for a wide range of applications and industries. This testing instrument offers a variety of features that facilitate and optimize your test processes. With automatic test sequences and results calculation, the user influence .Easy Hardness Testing. The Tru-Blue II Rockwell Hardness Tester comes with five preset load dwell times, including settings for NIST and plastics, and a useful connector to activate tests using a foot switch. It also provides instant computer-controlled application of forces through a .

Hardness Tester, also known as Hardness Testing Machine is used to determine hardness properties of materials, which are important for the evaluation of strength, wear resistance and ductility of the bulk materials or the surface coating. . Rockwell Hardness Tester. The range cover the scales of Rockwell, Superficial Rockwell & Brinell .sequence, with only simple handling test possibility. HR-430MR Rockwell hardness testing machine Smart type, but equipped with switching power steering and automatic brake handle for auto start feature. Motor drive controls loading sequence. HR-320MS Dual type (Rockwell/Rockwell superficial) hardness testing machineMacro hardness testing for your production or laboratory processes according to Vickers, Knoop, Brinell, Rockwell, carbon testing & plastics testing Load range from 0.3 to 3,000 kg More information and request for quotation. . When looking at the hardness testing machine in detail, you will clearly see the many hidden benefits resulting from .

Hardness test methods in the macro range include Brinell, Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf . In the past, the test force for hardness testing machines was applied by means of dead loads using weights. This means that a specific test force is .Principal : Digital Rockwell Hardness Testing Machine consists of forcing an indentor (Diamond or Ball) into the surface of a test piece in two steps i.e. first with preliminary test force and thereafter with additional test force and then measuring depth of indentation after removal of additional test force (Remaining preliminary test force active) for measurement of hardness .

rockwell hardness testing machine price

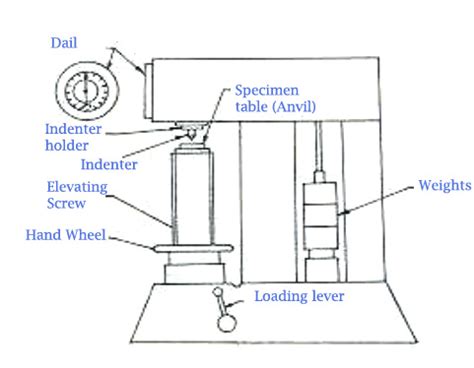

rockwell hardness testing machine diagram

The Rockwell hardness testing method fulfilled every requirement. After 100 years, it’s still the best metal strength test method. The Rockwell C scale is also the most precise way to report metal strength used in industrial machine .

Rockwell hardness testing machine has transformed how you assess material hardness, making it the go-to solution for professionals seeking unparalleled precision. From metals and alloys to plastics and ceramics, the Rockwell .The Wilson Rockwell 574 Hardness Tester Series stands out for its quality, durability, and leading Gauge Repeatability and Reproducibility (GR&R) in hardness testing instruments. . Keep your lab up and running with access .

rockwell hardness testers for steel

A complete range of hardness testers and hardness testing machines for Brinell, Rockwell, Knoop and Vickers hardness testing, as well as consumables and accessories – all designed to improve the accuracy and efficiency of your materialographic .

rockwell hardness tester price

According to DIN EN IS 6508-1 the result of a Rockwell hardness test is depicted as follows: 60 HRC W ⇒ Rockwell hardness value. 60 HRC W ⇒ Generic marker for "Hardness Rockwell" 60 HRC W ⇒ Label for the hardness scale. 60 HRC W ⇒ Label for the material of the indenter in case a ball is used (not shown for diamond cone)Rockwell hardness testers for all applications and scales, in laboratory and production on any steel and metal parts. Automatic, manual and portable. +39 0332 201 533. [email protected]. . Fully automatic hardness testing machine without motors, with test loads from 3 to 187,5 kgf. Rockwell, Superficial Rockwell and Brinell HBWT. ASTM E10: This standard covers Brinell hardness testing in metallic samples. ASTM E18: This standard includes the various ways that Rockwell hardness can be measured by standard methods, specifically for metallic materials. ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness .Bring material right to your bench to measure its hardness. These testers use a carbide indenter to take accurate Rockwell hardness readings every time. They come with a calibration certificate traceable to NIST that states they’ve passed a test for accuracy. With a durable metal body, these testers stand up to many environments, from heat treat facilities to workshops to inspection labs.

Universal hardness testers are designed for hardness testing according to Brinell, Vickers, Rockwell and Knoop, as well as plastics testing and carbon testing.To cover all of these test methods, the universal hardness testing machine supports a wide load range. ZwickRoell universal hardness testers therefore provide a flexible solution with a load range from 0.3 to .

rockwell hardness tester manufacturers

The DuraVision universal hardness testers for standard load ranges of 0.3-250 kgf or 3-3,000 kgf can be used for Vickers, Knoop, Brinell, and Rockwell tests, as well as for carbon and plastics testing.All methods are covered by the ISO 6506, ISO 6507, ISO 45452, ASTM E384, ASTM E92, ASTM E10, ISO 6508, ASTM E18, DIN 51917 and ISO 2039 standards. The DuraVision .While the Rockwell hardness test has its uniqueness, its accuracy is also guided by some critical factors you need to consider before engaging in this test method. Rockwell Testing Machine – The machine itself is one critical consideration for an accurate Rockwell test result. And though the Rockwell test is often seen as very easy and quick . Rockwell hardness testing is a common analytical technique for evaluating the hardness of metallics and synthetic materials. . Hardness Testers and Hardness Testing Machines From Zwick For A Range of Materials and Environments Including Testing In Situ; To begin the test, an initial test force, frequently called preload or minor load, is put .

Resultado da 1.59 1.78. . Bet on cricket soccer tennis. Best online sports betting website.

rockwell hardness tester machine|rockwell hardness testing machine diagram